In the power electronics control, transformation, driving, and signal transmission fields, cooling challenges have become the major constraint for the idealization of product developments. Liquid cooling techniques became the thermal management approach of priority. Winshare Thermal is providing all-around liquid cooling solutions and we are providing you with the thermal design, structural design, pipework assembly design of liquid and water cold plates and one-stop supplementary services.

Several liquid and water cold plate techniques are available for selection depending on the application scenarios.

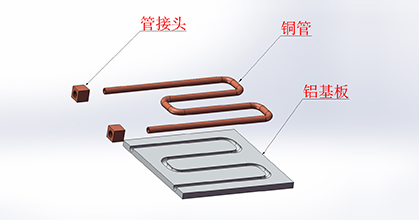

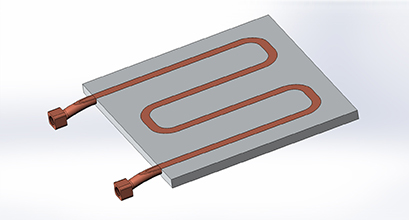

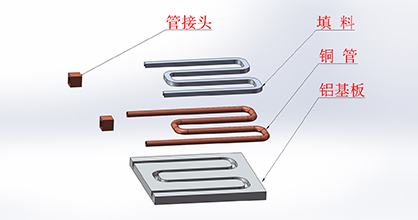

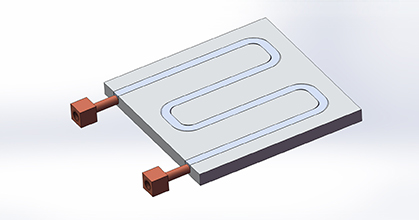

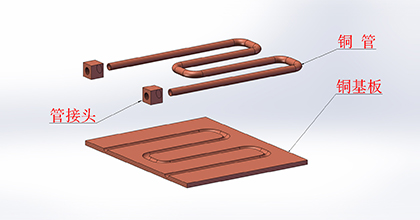

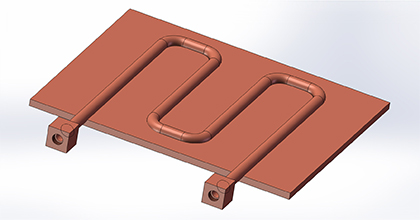

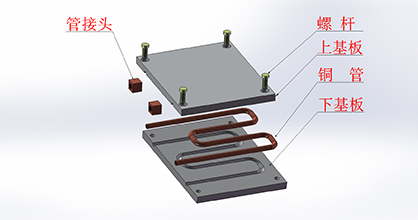

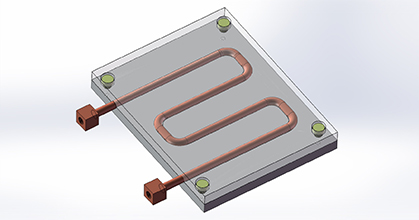

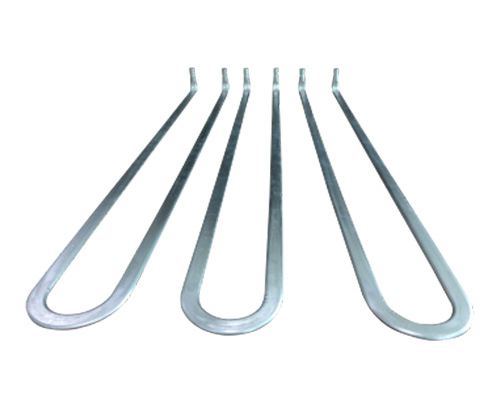

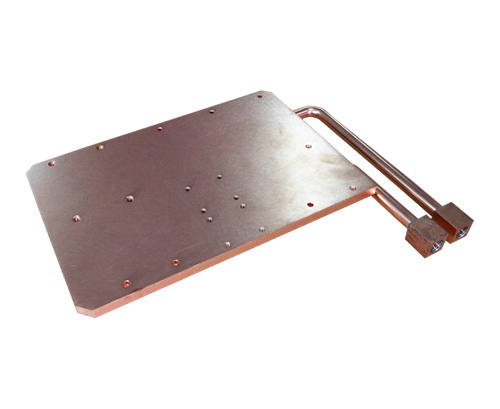

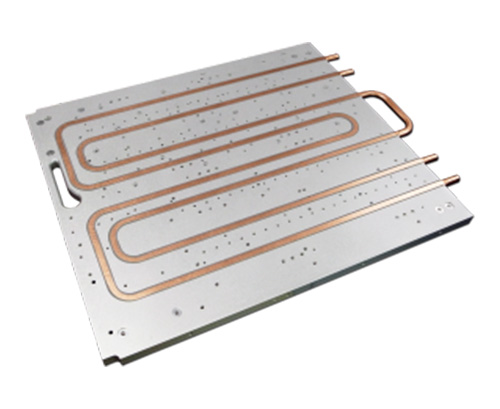

Buried-tube types:

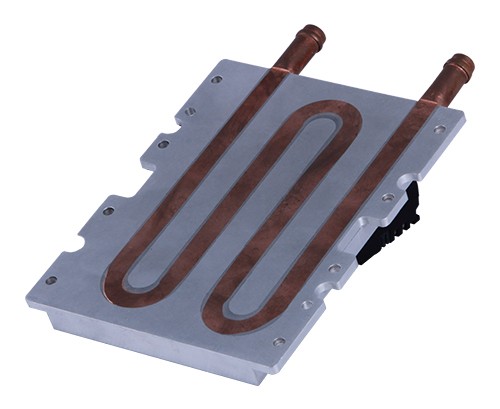

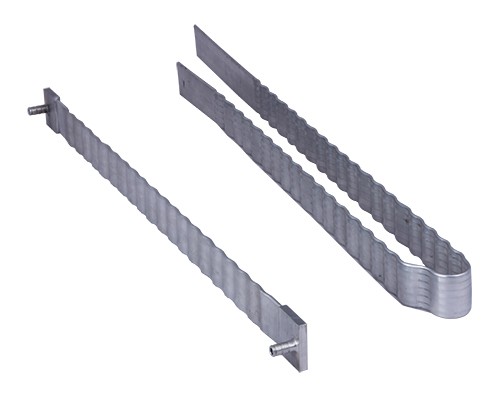

Exposed-tube technique: This technique applies to devices to be installed on one side. Copper tubes are pressed to deform into the grooves within an aluminum plate and then a fly-cut is applied to the surface. This allows the quick removal of heat due to the high thermal conductivity of copper tubes. Meanwhile, the lightweight of aluminum can reduce the total weight and keep the cost to a reasonable extent.

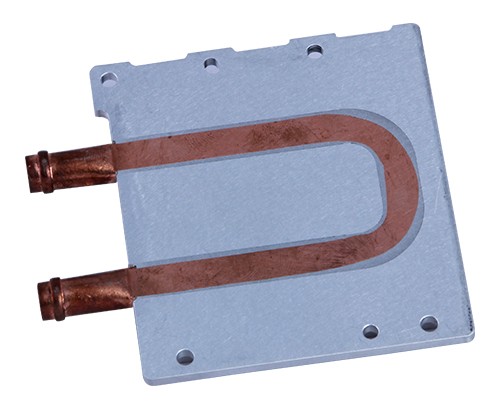

Full-buried-tube technique: The filler is a type of highly conductive epoxy resin which is imported from the US. When the temperature difference between two sides of a device is not critical, the cold plates can be applied to either just one side or both sides of the device. Since the copper tube thickness is not affected by any secondary machining and the application safety is ensured due to the protection of the filler, this technique is especially suitable for cold plate applications which use refrigerant as the cooling medium.

Half-buried techniques: This technique is suitable for the combination of copper plate + copper tubes. It can reduce the plate thickness and generate the weight reduction effect.

Sandwiched-tube technique: There are tubes between two plates and this technique is simple with lower cost. The combination could be aluminum plate + aluminum tubes/copper tubes/SUS tubes.

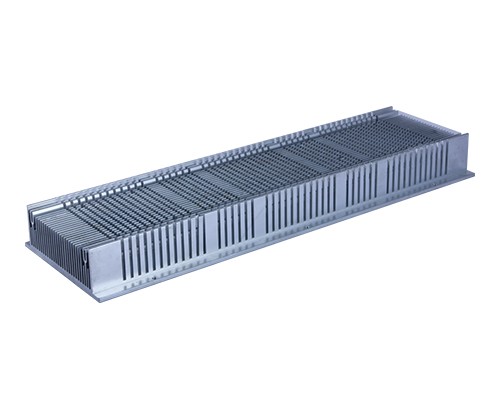

Micro-channels + friction welding:

Materials + welding

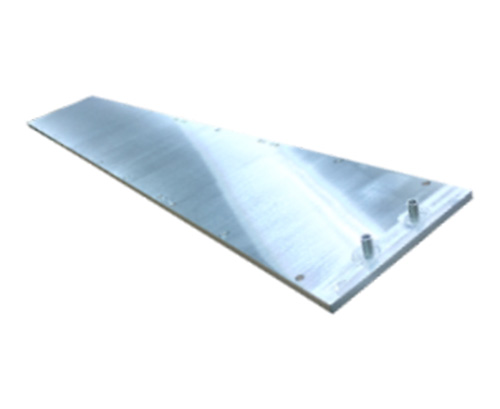

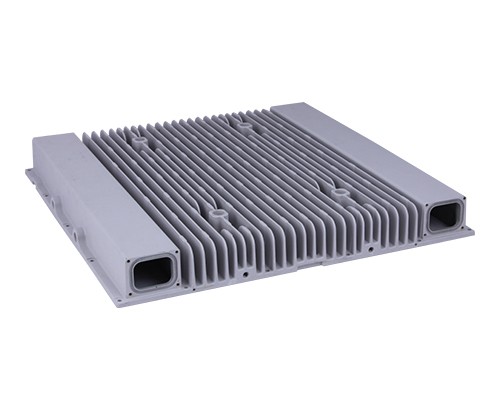

Extrusion techniques are used to form the flow passages of the cold plate directly and the flow passages are connected through by machining any blockage. The assembly is sealed by the friction welding technique with a high production throughput and low cost. This technique is not suitable for applications with higher power density or too many screw holes on the surface since this will create constraints for the flow passages. The main applications include the cooling of power batteries, heating devices, and integrated cooling products such as standard power modules.

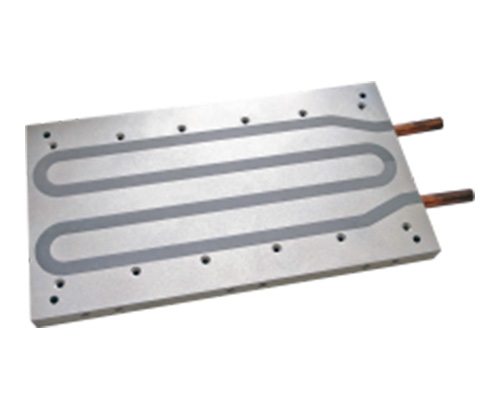

Machining + welding:

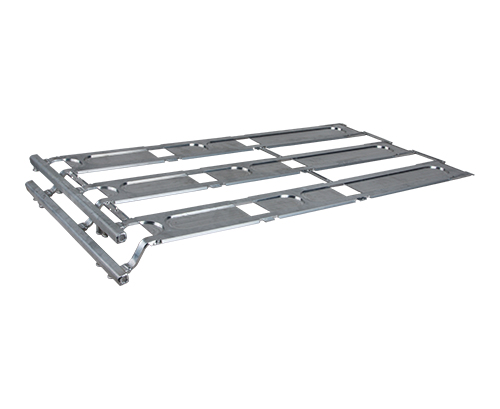

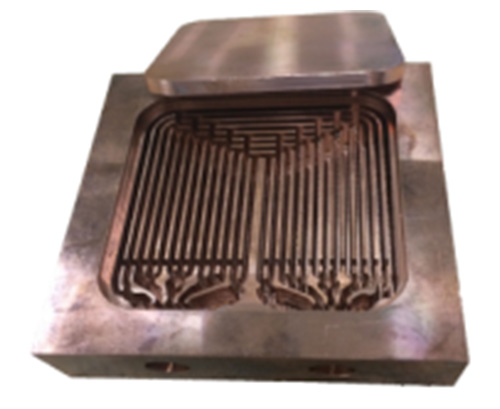

The dimensions and routes of the internal passages can be designed with greater freedom. This is suitable for thermal management products with a larger power density, irregular heat source layouts within a limited space. The main applications include wind power converters, electric motor controllers, lasers, special power supplies, and supercomputers and servers.

Die casting + welding:

Die casting technique is a mature and widely used approach for metal forming. With the fast development of new energy automobiles, this technique has become the first choice for the batch production of the cooling box for electric motor controllers. However, if the problems including die-casting impurities and voids are not effectively controlled, using seals or friction welding approaches still have the potential of critical leaking problems and therefore the failure rate remains high.

Winshare Thermal introduced the friction welding technique from Beijing Aeronautical Manufacturing Technology Research Institute in 2011. After years of research and verification on materials and sharpening our welding techniques, we have a good control of the re-welding technique on die-casting parts and have developed a stable process with the capability of batch deliveries.