- Product techniques

- Skived fin heat sink

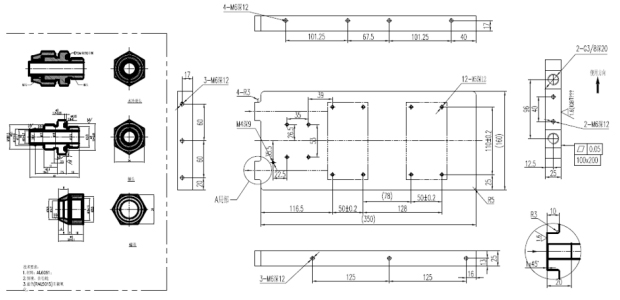

- Friction stir welded heat sink

- Heat pipe thermal module

- Water cooler

- Applications and industries

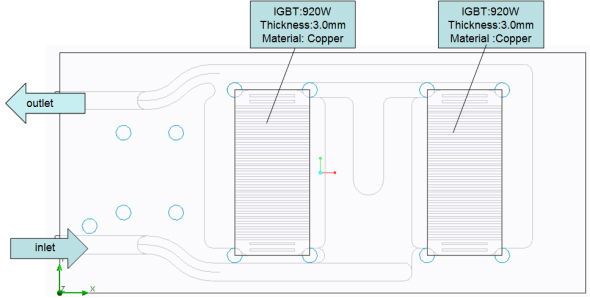

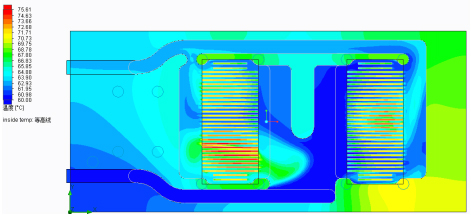

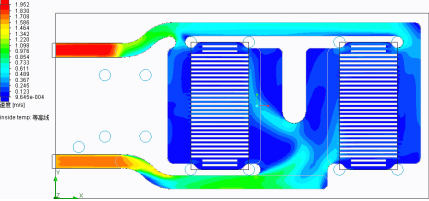

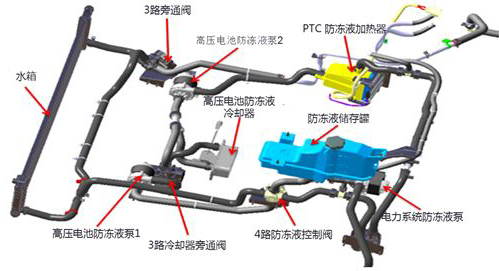

- Cooling solutions for electric car controllers

- Wind power converter cooling solution

- PV inverter cooling solution

- Energy storage system cooling solution

-

Official account

Official website

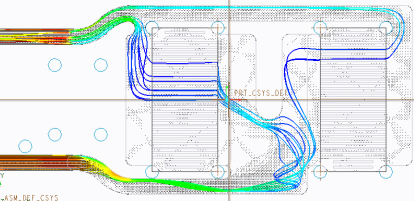

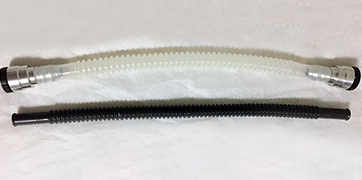

that utilizes the flow of liquids to quickly take heat away. Liquid cooling applications deal with liquid cooling plates (also called water cooling plate) that are installed onto heat sources. It works together with heat exchangers and pumps to dissipate heat by the circulation of liquid. Under typical conditions, liquid cooling applications are used in an environment with higher thermal energy density that either forced convective cooling or phase change system are not able to meet the required cooling effect.

that utilizes the flow of liquids to quickly take heat away. Liquid cooling applications deal with liquid cooling plates (also called water cooling plate) that are installed onto heat sources. It works together with heat exchangers and pumps to dissipate heat by the circulation of liquid. Under typical conditions, liquid cooling applications are used in an environment with higher thermal energy density that either forced convective cooling or phase change system are not able to meet the required cooling effect.